Electric Container Loading System (e-CLS)

General Data

Lifting height: 1970 mm/ 6′ 59⁄16"

Maximum capacity: 50 kg/ 110 lbs

Load capacity: Minimum 10 bags/minute

Vertical speed: 0,4 m/s (adjustable)

Media: 230 V/ 850 W

Article no: 96-10079 (left) 96-10085 (right)

Brochure: Baggage Handling Made Easy

Fast, Manual Push Loading with Ergonomic Support

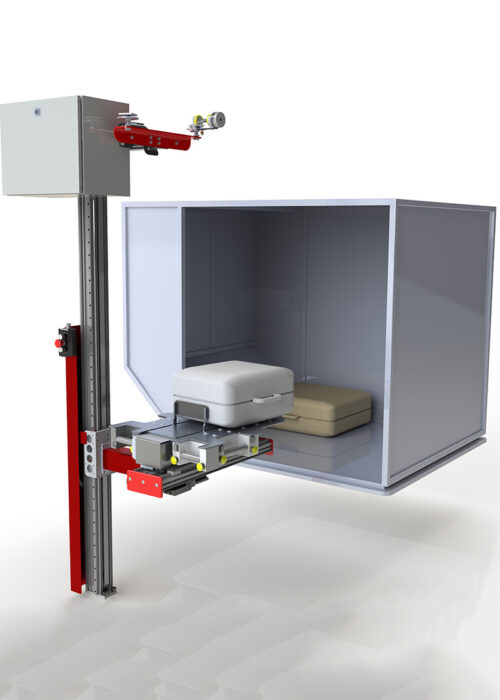

The original e-CLS (without Launcher function) is a reliable and ergonomic Electric Container Loading System designed to streamline the loading process, making it more efficient, safe, and cost-effective.

This innovative system is perfect for airports looking to improve their logistics operations, reduce costs, and increase productivity.

The container loader showcases efficiency and safety features for loading various types of cargo. The container loading machine is an efficient solution for quickly loading materials into shipping containers.

- The system includes a loading plate that works alongside adjustable legs and hydraulic mechanisms to securely hold and manage cargo during the loading process.

- The loading plate is automatically unlocked when the operator grips the handle.

Luggage is rolled smoothly onto a telescopic platform and manually pushed into containers, helping reduce strain and improve workflow efficiency at airports worldwide.

Key Benefits

Quick Lifting

Easily roll bags on and off the platform for rapid loading and unloading.

Ergonomic Handling

While loading remains manual, the design minimizes bending and lifting, reducing physical fatigue and injury risks.

Customizable Configuration

The cargo loading solution is flexible and can be adapted for left- or right-side lateral loading to suit your facility layout.

Universal Design

Suitable for both left- and right-handed operators, providing flexibility and ease of use.

Compact and Efficient

Designed to perform in tight spaces, the e-CLS enhances workflow without taking up extra room.

Applications

The e-CLS without Launcher is perfect for airport environments seeking a fast, efficient, and ergonomic alternative to manual lifting, while still allowing operators full control of the loading process. It is part of a new generation of baggage loading systems that offer intuitive handling, space efficiency, and improved safety.

Do you wish to learn more about effortless baggage loading by the press of a button? Read about our e-CLS with launcher function here.

The e-CLS reduces the risk of spinal disc compressions that may ultimately cause back injuries.

The e-CLS enables you to load from both high and low laterals into containers.

Loading from moving lateral into a container is also easy with the E-CLS.

Easy to maneuver

The machine is equipped with brakes that can lock the table in all directions. When the operator grips the handle, the table is automatically unlocked, and the e-CLS is ready for use! Baggage is loaded onto the table, which the operator can move vertically or horizontally, and unloading takes place without any heavy lifting. The traverse system makes the e-CLS mobile and easy to work with. Bags move friction-free because of the metal ball rollers on the table.

The e-CLS is equipped with four control buttons for vertical movements, one on each side of the handle. These buttons also control the built-in lamps that shine into the container, making it easier to see where to place the bag. The jog buttons on the pillar make it possible to raise and lower the table past its working position, when the maneuvering handles are too high to be reached. With a push of the “up” button, the table is raised up and parked at the top. It automatically goes into sleep mode/power save mode, out of the way of the baggage handler. The next time it’s needed it can easily be lowered with the “down” jog button.

Safety functions

A red emergency stop button is strategically placed on the pillar of the cargo loading solution. As soon as it is activated, it immediately cuts the power supply, and the machine stops in its tracks. The machine also senses if the load is too heavy and will automatically stop operation. These features reduce the risk of unforeseen injuries caused by overloads.

The e-CLS is CE Certified in accordance with both the EU Machine Directive 2006/42/EC and the Low Voltage Directive 2014/35/EU, ensuring full compliance with stringent European safety standards. It is equipped with a hold-to-run control system, which means the machine only operates while the operator actively maintains grip on the control handle, eliminating the risk of unintentional motion. The design also minimizes any risk of crushing injuries, further enhancing operational safety.

To support safe and confident use, we at Lifts All provide comprehensive training for every customer, ensuring they understand how to operate their new lifting tool effectively.

With its safety-first design, regulatory compliance, and ease of use, the e-CLS is a dependable and future-ready solution for any airport seeking to streamline baggage handling while prioritizing worker safety.