What is a Jib Crane?

A portable jib crane is a type of lifting equipment designed for versatility and mobility, featuring a horizontal arm (the jib) that rotates to lift and move materials within a specific area. Unlike fixed jib cranes, portable models can be moved to different locations as needed, often with the aid of a fork truck. They are particularly useful in tight spaces, small workshops, or when overhead cranes are impractical. Whether you need to lift heavy materials, equipment, or other loads, a jib crane provides an efficient and reliable solution for your lifting needs.

Key Features and Benefits:

- Portability: The main advantage is their ability to be moved easily, either by forklift or other means, allowing them to be used in multiple locations.

- Versatility: They can be used in a variety of settings, including manufacturing plants, warehouses, and construction sites.

- Space Efficiency: Portable jib cranes can operate in areas with limited overhead space or where a full-sized crane isn’t feasible.

- Reduced Setup: They often don’t require a concrete foundation, unlike some fixed jib cranes, which simplifies setup and relocation.

- Specific Applications: They can be used for repetitive lifting tasks, loading and unloading materials, and assisting with assembly or maintenance.

Here’s a breakdown of how they work:

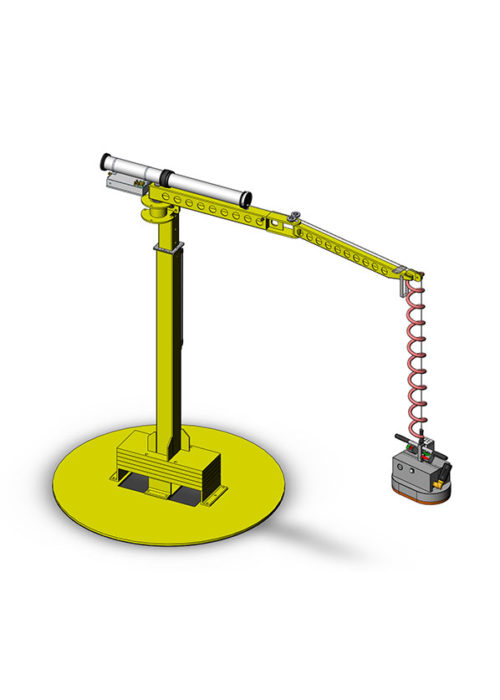

- Support Structure: A vertical support (pillar) provides the foundation for the jib.

- Jib Arm: The horizontal arm, or jib, extends from the support and is capable of rotating, often 360 degrees, depending on the design. It can also be folded.

- Hoist: A hoist, typically with a chain or wire rope, is attached to the jib and moves along its length, enabling vertical lifting and lowering of the load.

- Rotation: The jib can rotate around the vertical support, allowing the hoist to cover a circular area.

- Mobility: Portable jib cranes are designed to be moved between locations, utilizing forklift tubes for easy transport.

- Power: They can be powered by electricity or pneumatically (using compressed air), depending on the model and application.

- Control: Operators use controls to manage the hoist’s lifting and lowering.

- Applications: Portable jib cranes are commonly used in manufacturing, warehouses, and construction sites for tasks such as loading and unloading materials, assembly line work, and moving items within a defined area.

In summary, portable jib cranes offer a flexible and efficient solution for lifting and moving materials in various settings, particularly where mobility and space are important considerations.

Benefits of Portable Jib Cranes

Portable jib cranes offer a range of benefits including increased productivity, improved safety, and flexibility in various industrial settings. They are particularly advantageous for their ease of installation, space-saving design, and ability to handle loads in tight spaces.

Enhanced Safety:

- Reduced Lifting Injuries: Jib cranes minimize the need for manual lifting, which can lead to strains, sprains, and other injuries.

- Precise Control: Their design allows for precise control and movement of loads, reducing the risk of accidents during lifting and positioning.

Increased Productivity and Efficiency:

- Streamlined Lifting Operations: Jib cranes automate the lifting process, reducing downtime and improving workflow efficiency.

- Space Optimization: Their compact design allows for placement in tight spaces and around obstacles, maximizing the use of available workspace.

- Reduced Reliance on Multiple Workers: Jib cranes can handle heavy loads that would otherwise require multiple people, freeing up labor for other tasks.

Faster Loading and Unloading:

They can significantly reduce the time it takes to load and unload materials, improving overall productivity.

Flexibility and Versatility:

- Relocation: Portable jib cranes can be easily moved and repositioned to different areas of a facility as needed, unlike permanent cranes.

- Adaptability: They can be used in various industrial applications, including manufacturing, warehousing, and shipping, according to industrial equipment providers.

Integration with Other Systems:

Jib cranes can be integrated with other automated systems and workflows, further enhancing efficiency and productivity.

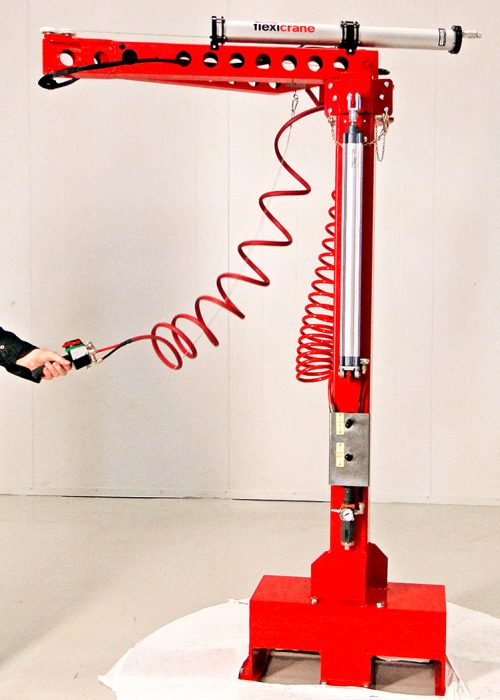

- 360-degree Rotation: Lifts All’s FlexiCrane Mobile offers a full 360-degree rotation, allowing for greater coverage and flexibility in lifting and moving loads.

- Accommodates Various Tools: They can support lifters and hoists, expanding their functionality.

- Space-Saving Design: Jib cranes can be mounted on walls or floors, optimizing workspace utilization.

Common Applications of Jib Cranes Include

- Manufacturing: For handling parts and machinery in production lines.

- Warehousing: For efficiently moving equipment within storage facilities.

- Shipping and Receiving: For loading and unloading items in warehouses.

Overall, jib cranes are a reliable and efficient lifting solution that enhances productivity and safety across various industries.

What Size of Portable Jib Crane Do I Need?

To determine the right size portable jib crane, you need to consider the maximum weight of the loads you’ll be lifting, the reach (boom length) needed, and the lifting height required. Additionally, you’ll want to evaluate the environment and workplace layout to ensure the crane’s rotation and movement are suitable.

Load Capacity:

- Calculate the maximum weight: Determine the heaviest item you need to lift, including any attachments or rigging.

- Determine the heaviest item: Identify the heaviest item you need to lift and add a safety margin. The crane’s rated capacity should exceed this weight.

- Safety factor:

Lifts All conducts thorough testing to ensure the crane’s actual capacity exceeds the rated capacity (maximum load), to prevent overloading and ensure safe operation, taking into account dynamic forces and potential impacts. In calculating safety and durability, an FOS (factor of safety) of 1.6is typically applied above the maximum expected load weight.

Reach and Height:

- Boom Length: Measure the distance from the center of the mast to the farthest point you need to reach with the load, according to crane sizing guidelines.

- Height Under Boom (HUB): Determine the vertical distance needed to lift the load to its desired height, accounting for the height of the load and any lifting equipment.

- Consider obstructions: Ensure the boom length allows for easy movement and positioning of loads without colliding with obstacles.

Portability and Rotation:

- Mobility: If you need to move the crane around, Lifts All’s FlexiCrane Mobile is perfect with its forklift pockets.

- 360-degree Rotation: If you need to access loads from all directions, FlexiCrane Mobile offers full rotation.

Other Factors:

- Workspace: Assess the available space for the crane’s footprint and swing radius.

- Rotation: Consider the swing radius and ensure it allows you to position loads without obstructions.

- Durability: Consider the environment where the crane will be used and choose a model that can withstand those conditions.

- Budget: Portable jib cranes are available in a range of prices.