Lifting Tools for Cleanrooms – When Hygiene and Precision Are Critical

In environments where cleanliness and hygiene are absolutely essential – such as in the pharmaceutical and food industries – lifting solutions must not only be ergonomic and efficient. They also have to be constructed to meet the highest requirements for sterility and contamination control. In this article, we’ll take a closer look at what defines a cleanroom, why specialized equipment is necessary, and how Lifts All’s lifting tools are designed to meet those specific needs.

Why Specialized Lifting Tools Are Needed in Cleanrooms

Cleanrooms are designed to maintain a strictly controlled level of airborne particles – sometimes as few as a handful per cubic meter. This is regulated by the international standard ISO 14644. The lower the particle count, the higher the cleanliness classification – and the higher the requirements on the equipment used.

In such environments, even microscopic dust particles, skin flakes or oil residues can negatively affect the product. That’s why every step of production must be designed to prevent dirt or contamination.

Standard lifting systems are well-suited for most industrial environments. However, in cleanrooms with strict hygiene requirements, equipment must meet specific standards, such as:

• Be made from non-porous, hygienic materials

• Withstand disinfection and rigorous cleaning with alcohol or other strong agents

• Feature smooth, polished surfaces and edges

• Be non-shedding – does not release particles or oils

Customized Solutions for Cleanrooms

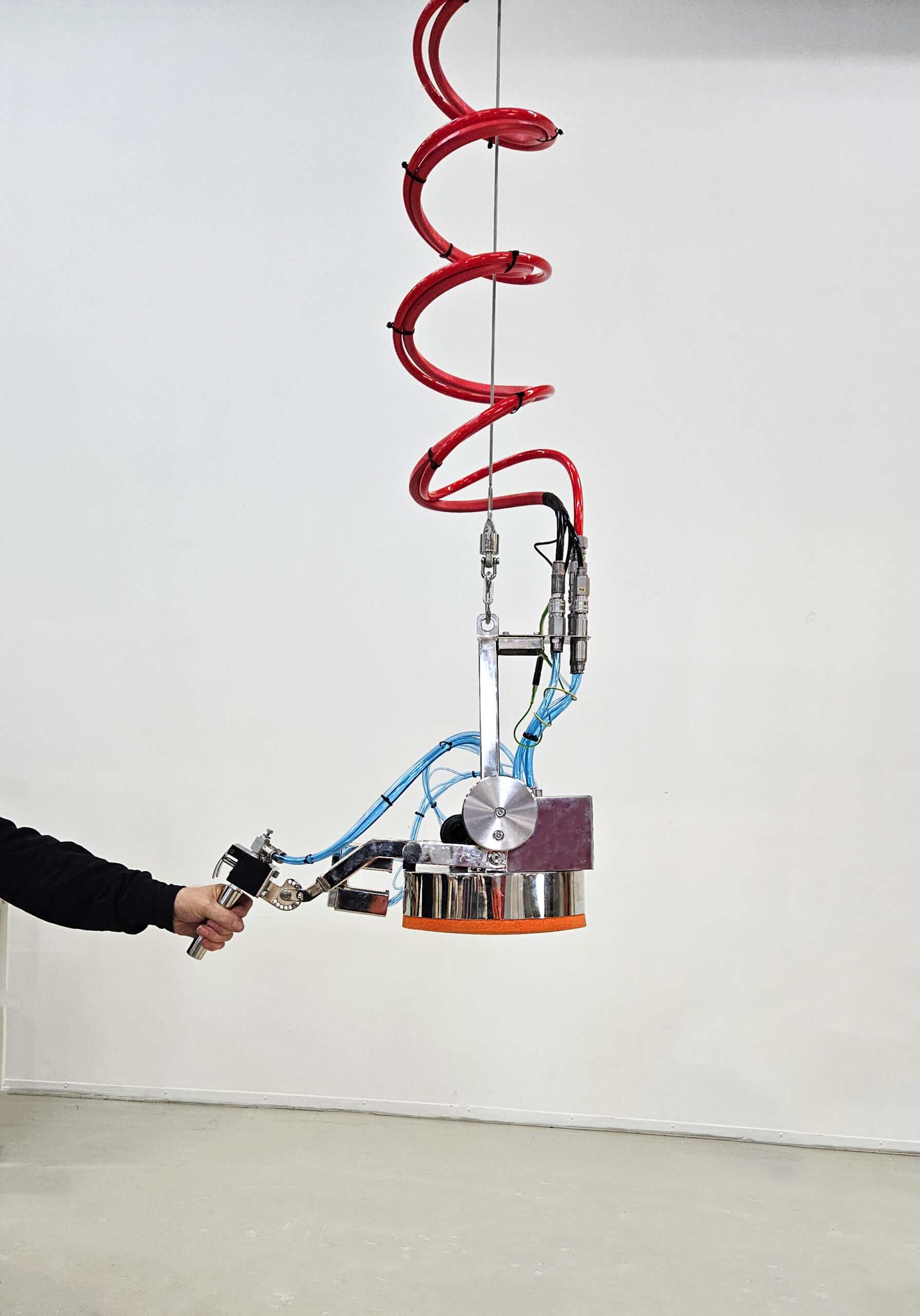

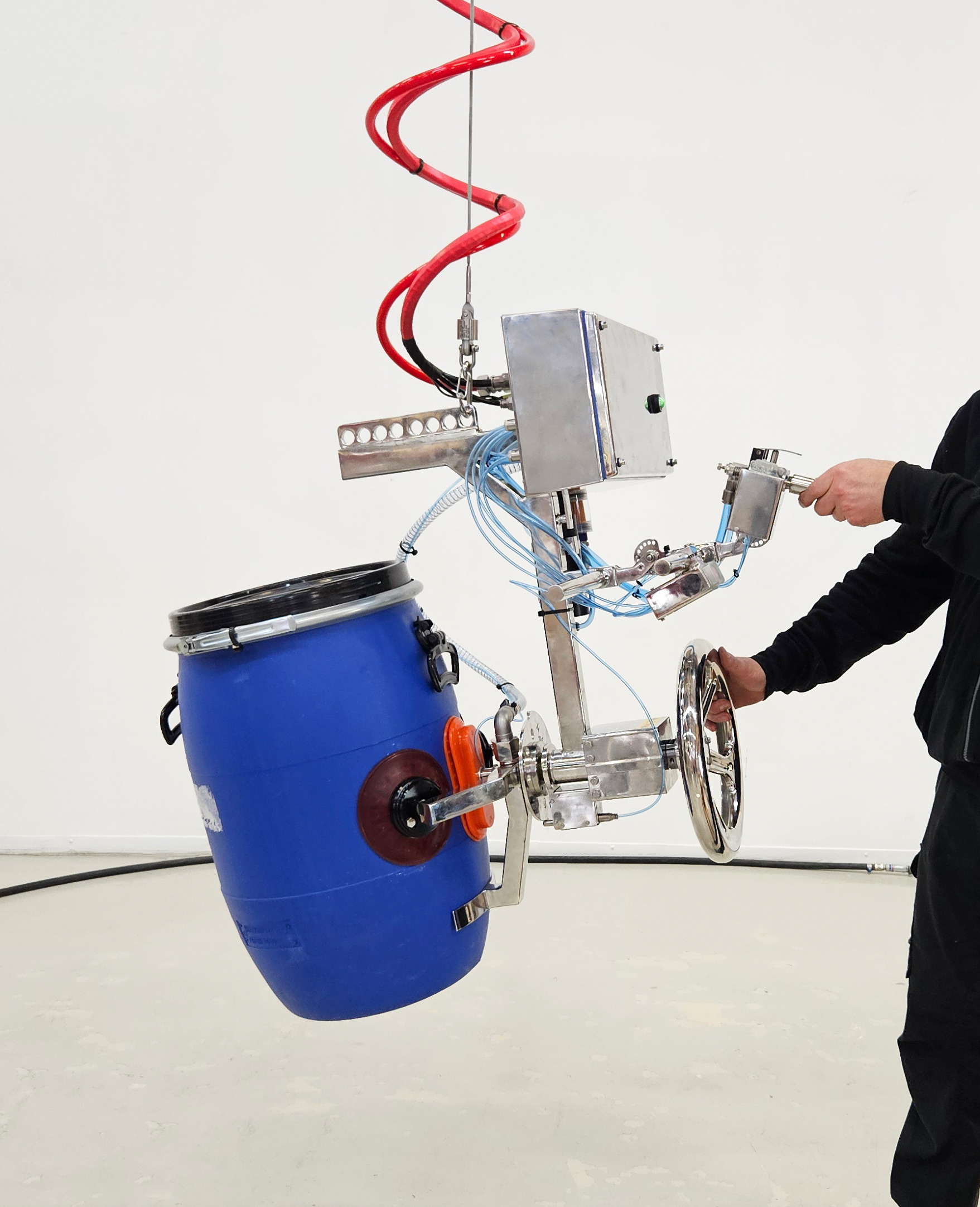

To meet the specific demands of cleanroom environments, we offer lifting tools made from highly polished stainless steel. Our tools have weldings that prevent the build-up of dirt and bacteria. Their construction allows for thorough cleaning – even with alcohol and other disinfectants several times a day. Many of our products can also be used in ATEX environments. This means that they are safe for use in areas where there is a risk of explosion from gases, vapors, or powder-like substances.

If you have specific requirements – for example, FDA-approved materials – we provide a Cleanroom Form to ensure that all your needs are met. The form is completed under consultation with us, helping us deliver the right solution for your cleanroom application.

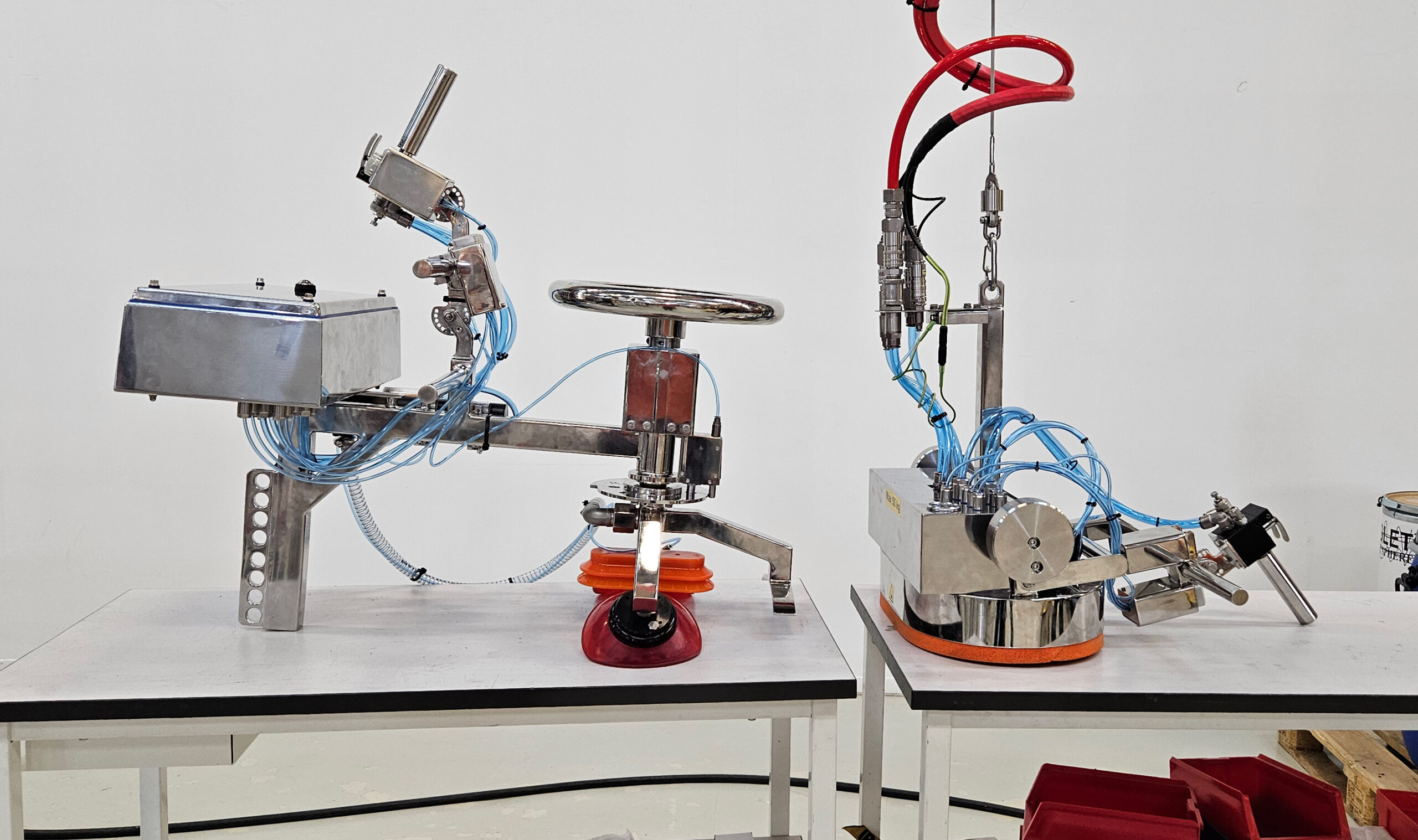

Our wide range of cleanroom lifting tools – all of which can be customized in both form and function:

1. Vacuum Grippers

Perfect for lifting flat or airtight items such as boxes, plastic drums, bags, or sacks containing sensitive contents. The pneumatic system can be designed to lead the air out of the cleanroom.

2. Mechanical Grippers

Grippers that latch on from the side or top – ideal for handling containers, jars, tubes, buckets, or porous sacks. (To ensure optimal hygiene, all control buttons and levers can be covered.)

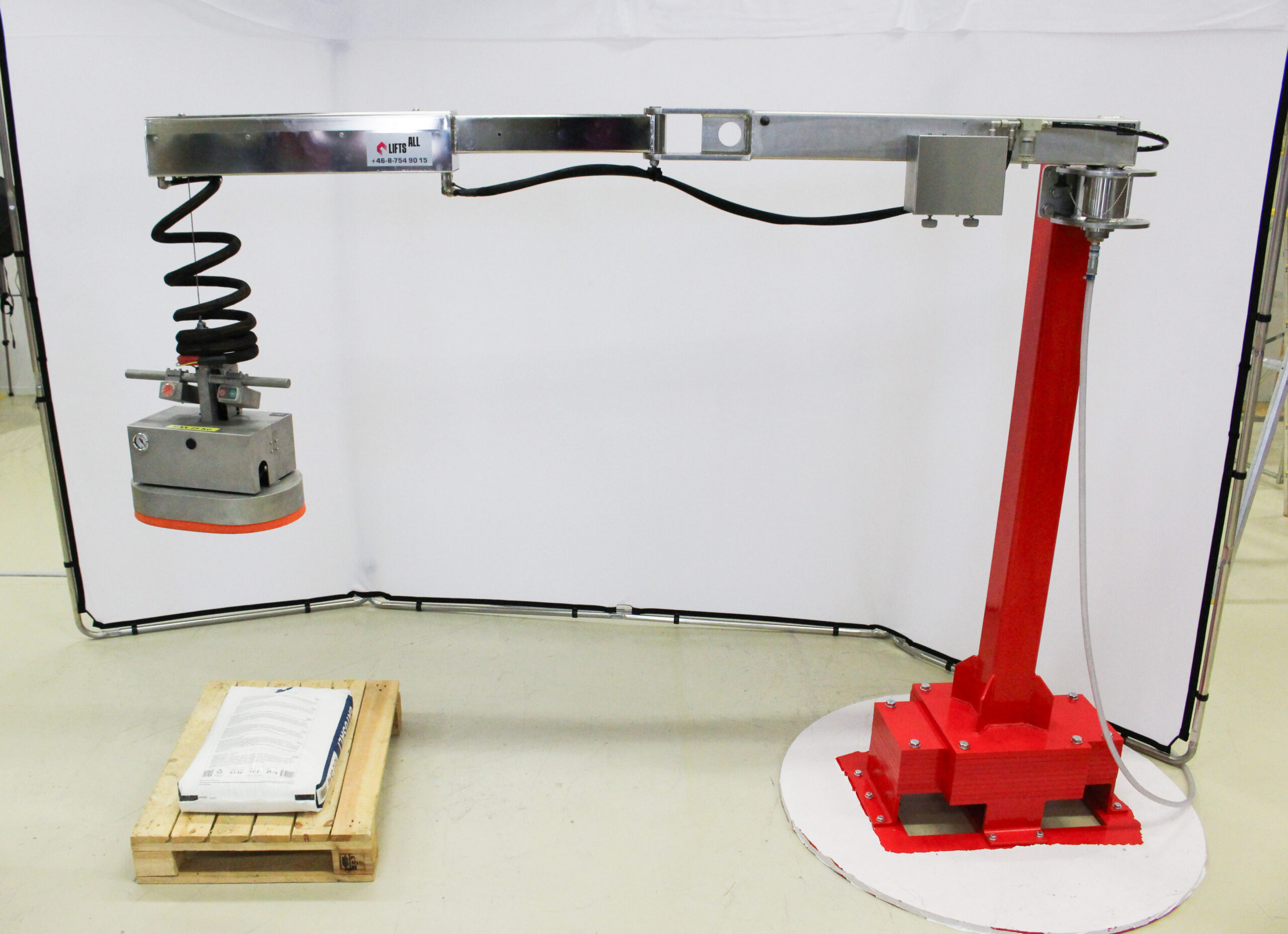

3. Rail Systems and Articulating Jib Cranes

We also offer suspension systems for our grippers – rail systems and cranes made from cleanroom-approved materials. They can be mounted on ceilings or walls and include sealed or stainless components suitable for sterile environments.

You can find examples of lifting solutions we’ve created for the pharmaceutical industry here, and examples for the food industry here.

Clean Air

Our lifting solutions are powered by compressed air, an environmentally friendly and energy-efficient alternative to direct electricity. In cleanroom environments, the system can be adapted to direct the used air out of the room, preventing particle recirculation and maintaining the room’s cleanliness classification.

Designed For Your Needs

Every cleanroom is unique – and so are our lifting tools. In collaboration with our customers, we develop grippers and solutions based on the materials being handled, the facility’s workflow, and specific hygiene requirements. Whether you’re lifting sensitive components, heavy sacks, or bulky containers, we ensure that lifting is carried out ergonomically, safely, and hygienically.

Efficiency and Ergonomics – Without Compromise

Manual lifting in controlled environments isn’t just physically demanding – it can also pose a risk to the product. Our lifting aids reduce the risk of handling errors, injuries, and contamination while improving the work environment. With over 5,000 unique lifting solutions in our portfolio, we have the tools and experience to improve daily operations even in the most demanding settings.

Want to Learn More?

Contact us to learn how our cleanroom lifting tools can enhance both workplace safety and product integrity in your operations.

More news articles

Meet Us at the Maintenance Fair 2026

We are excited to exhibit at Underhåll- the Maintenance Fair 2026, where we will showcase ergonomic and efficient lifting solutions for …

Read more

Meet a coworker: Emilia

Emilia has been working at Lifts All since May 2022. With experience as an entrepreneur and a strong interest in people, she combines both heart …

Read more

This Year’s Christmas Donation Goes to Doctors Without Borders and BalticWaters

Lifts All continues its tradition of supporting organizations that make a real difference. This year, our Christmas donation goes to two …

Read more